Mercedes' seatbelt pretensioner systems, integrated with the Airbag ECU, actively tighten belts during collisions, reducing ejection risk and severe injuries. Data logged within the ECU offers valuable insights for engineers to optimize pretensioner performance through force impact, extension rates, and component responses analysis, enhancing overall vehicle safety. Continuous monitoring ensures these advanced systems function optimally in auto repair processes.

Mercedes-Benz has long been at the forefront of automotive safety innovations, and one such advancement is the sophisticated seatbelt pretensioner system. This article delves into the inner workings of these mechanisms, focusing on how Mercedes stores deployment logs within the Airbag Electronic Control Unit (ECU). By analyzing these logs, engineers can refine safety measures, ensuring optimal protection for passengers in collision scenarios. Understanding the seatbelt pretensioner’s role within the ECU offers valuable insights into enhancing vehicle security.

- Understanding Mercedes Seatbelt Pretensioner Systems

- The Role of the Airbag ECU in Seatbelt Deployment

- Data Logging and Analysis for Improved Safety Measures

Understanding Mercedes Seatbelt Pretensioner Systems

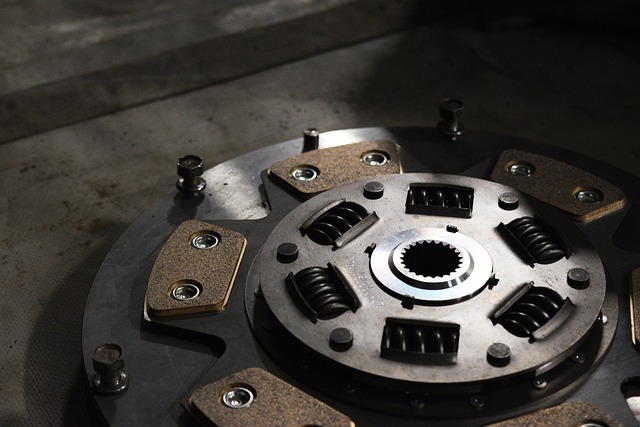

Mercedes Seatbelt Pretensioner Systems are advanced safety mechanisms designed to secure occupants during a collision, playing a crucial role in auto safety. When a crash is detected, pretensioners actively tighten seatbelts, minimizing the risk of ejection and severe injuries. These systems are integral to Mercedes’ reputation for engineering excellence, incorporating cutting-edge technology to ensure optimal passenger protection.

Understanding how these pretensioners operate involves grasping their integration with the Airbag Electronic Control Unit (ECU). The ECU acts as a central command center, monitoring vehicle sensors and airbags, including seatbelt pretensioners. In case of an accident, it swiftly initiates deployment protocols, causing the pretensioners to retract and tighten seatbelts, offering a crucial fraction of seconds for occupants to prepare for impact. This seamless integration is why maintaining and logging these systems’ performance, such as through stored data in the ECU, is vital for efficient auto repair services and overall vehicle safety.

The Role of the Airbag ECU in Seatbelt Deployment

The Airbag Electronic Control Unit (ECU) plays a pivotal role in Mercedes seatbelt pretensioner deployment logs and overall vehicle safety. This advanced computer system acts as the brain for both airbag activation and pretensioner functionality, ensuring the utmost protection for occupants during accidents. When a collision is detected, the ECU swiftly initiates the appropriate response by deploying airbags and tightening seatbelts to reduce impact forces.

The Mercedes seatbelt pretensioner, integrated into the ECU, is designed to minimize the risk of injuries by rapidly retracting and tightening seatbelts. This mechanism works hand-in-hand with airbags, providing a comprehensive safety net during vehicle repair and enhancing the overall car repair services experience for drivers. By accurately recording deployment logs, the ECU allows auto body restoration specialists to analyze and optimize pretensioner performance, ensuring the best possible outcomes for both passengers and vehicle maintenance.

Data Logging and Analysis for Improved Safety Measures

The Mercedes seatbelt pretensioner deployment logs stored within the Airbag Electronic Control Unit (ECU) offer a wealth of data that can significantly enhance vehicle safety measures. By meticulously analyzing these logs, automotive engineers and researchers gain valuable insights into the performance and effectiveness of pretensioners during real-world scenarios, including unexpected events like automotive collisions. This data logging process involves capturing critical information such as the force of impact, seatbelt extension rates, and individual component responses, which are then scrutinized to identify areas for improvement.

Through advanced data analysis techniques, auto body shops and manufacturers can pinpoint potential weaknesses in pretensioner design and deployment sequences. Such insights lead to innovative solutions that could further protect occupants during high-impact incidents. Moreover, continuous monitoring of these logs aids in optimizing the overall safety system, ensuring that the Mercedes seatbelt pretensioners function optimally and contribute to reducing the severity of injuries in the event of an accident, thereby enhancing the role of auto painting services as part of post-collision repair processes.

Mercedes seatbelt pretensioners play a crucial role in enhancing vehicle safety, and their effective deployment is pivotal. By logging and analyzing data within the Airbag ECU, manufacturers can significantly improve these systems. This process allows for a deeper understanding of seatbelt pretensioner behavior, leading to refined safety measures and potentially saving lives. The integration of detailed deployment logs in the ECU is a game-changer, enabling engineers to navigate and optimize the intricate processes that ensure passenger protection during accidents.